Unveiling an Extensive Choice of Durable Undercarriage Parts for Heavy Machinery

Unveiling an Extensive Choice of Durable Undercarriage Parts for Heavy Machinery

Blog Article

Crucial Overview to Undercarriage Parts for Heavy Tools

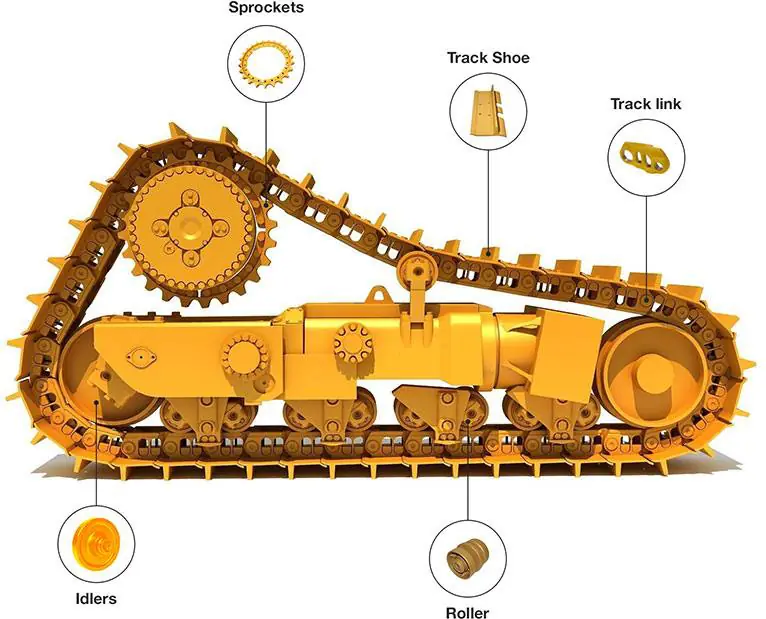

When it comes to hefty equipment, the undercarriage plays a crucial duty in ensuring reliable and smooth operations. From track chains to rollers and idlers, each part contributes to the general capability of the tools.

Significance of Undercarriage Components

Recognizing the crucial function that undercarriage parts play in the efficiency and longevity of heavy equipment is critical for efficient maintenance and operation - undercarriage parts. The undercarriage elements create the structure on which the whole maker runs, sustaining the weight of the tools, providing stability, and soaking up shock lots throughout procedure. A properly maintained undercarriage not just makes certain smooth procedure yet also contributes considerably to decreasing downtime and repair work costs

The undercarriage consists of numerous important components such as track chains, track shoes, gears, idlers, rollers, and track frames. The track chains and track footwear help in giving traction and assistance, while the sprockets and idlers aid in driving the tracks efficiently.

Sorts Of Track Chains

Track chains are important parts of heavy devices undercarriages, giving the essential grip and assistance for efficient procedure. There are largely two kinds of track chains utilized in hefty equipment: sealed and lubed track chains (SALT) and completely dry track chains. Sealed and oiled track chains are typically discovered in modern-day heavy machinery. These chains are pre-lubricated and secured to avoid dust, particles, and moisture from getting in the chain joints, making certain smooth procedure and prolonging the chain's life expectancy. On the various other hand, completely dry track chains need normal manual lubrication to preserve ideal efficiency and protect against premature wear.

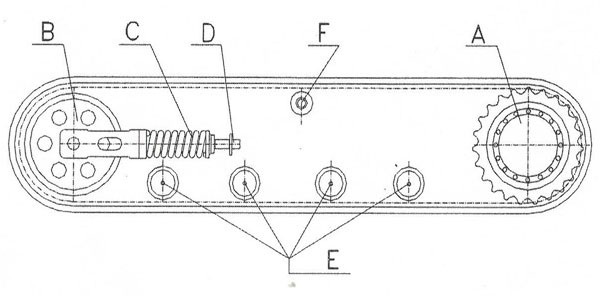

Function of Rollers and Idlers

Rollers and idlers play a vital role in sustaining and directing the track chains of hefty tools undercarriages, adding to the overall security and effectiveness of the machinery. Rollers are created to sustain the weight of the equipment and give a smooth surface area for the track chain to relocate along. They help distribute the weight equally, decreasing extreme endure the track chain and ensuring appropriate traction. Idlers, on the various other hand, overview the track chain and help preserve correct tension throughout the undercarriage system. By leading the track chain in a controlled manner, idlers protect against excessive side-to-side motion, lowering the risk of derailment and irregular wear.

With each other, rollers and idlers operate in harmony to make certain that the track chain remains in area, even on rough terrain, improving the devices's efficiency and longevity. Correct maintenance and routine examination of rollers and idlers are important to stop early wear and possible breakdowns, ultimately maximizing the efficiency and life expectancy of hefty devices undercarriages.

Recognizing Gears

One vital aspect of gears is guaranteeing correct positioning and tension to avoid early wear and damages. Misaligned sprockets can cause unequal endure the track chain, resulting in decreased effectiveness and potential security hazards. Routine upkeep and assessment of sprockets are necessary to determine any kind of signs of wear or imbalance without delay.

Furthermore, sprockets are available in various sizes and tooth arrangements, depending on the particular hefty tools and its designated use. Correct choice of gears based on the devices's specifications is important to make certain optimal efficiency and longevity of the undercarriage system. Understanding the function of visit the website gears and their upkeep requirements is crucial for taking full advantage of the performance and lifespan of heavy equipment undercarriages.

Maintenance Tips for Durability

To ensure the prolonged durability and ideal functionality of hefty tools undercarriages, persistent upkeep techniques are vital. Consistently checking undercarriage components such as track footwear, rollers, idlers, and gears for wear and tear is vital. Appropriate track stress adjustment is likewise crucial for reducing premature wear on undercarriage components.

Verdict

To conclude, undercarriage components are essential elements for hefty tools, playing crucial functions in keeping security and functionality. Comprehending the various sorts of track chains, idlers, rollers, and sprockets is very important for proper maintenance and durability of the tools. By following maintenance suggestions and consistently inspecting and replacing used components, operators can make sure the optimum performance and efficiency of their heavy machinery. Correct treatment and interest to undercarriage components are essential to maximizing tools life-span and performance.

The undercarriage consists of numerous crucial components such as track chains, track footwear, sprockets, idlers, rollers, and track structures. The track chains and track shoes assist in go to my site giving grip and support, while the sprockets and idlers help in driving the tracks smoothly (undercarriage parts). There are primarily 2 kinds of track chains utilized in heavy tools: secured and lubricated track chains (SALT) and completely dry track chains. Appropriate selection and upkeep of track chains are critical to ensure the general performance and longevity of hefty equipment undercarriages

Sprockets are essential components of hefty tools undercarriages, responsible for moving power from the machinery to the track chain.

Report this page